In the intricate dance of manufacturing, where precision and timing are paramount, the lifeblood that keeps the machinery whirring and the conveyor belts moving is not just the raw materials or the skilled labor—it’s cash flow. For small manufacturers, mastering the art of cash flow management is not merely a strategy for growth; it is a survival technique. In industries characterized by tight margins, fluctuating demand, and an incessant push for innovation, the ability to forecast and optimize cash flow can mean the difference between thriving and barely surviving.

Small manufacturing businesses, with their unique challenges such as managing inventory costs, navigating payment terms with suppliers and customers, and funding capital expenditures, are particularly susceptible to the perilous impacts of a cash crunch. A single misstep in cash flow management can stall production lines, hinder the ability to meet customer orders, and ultimately jeopardize business viability.

Yet, despite its critical importance, effective cash flow management remains an elusive grasp for many. The reasons vary, from a lack of understanding of cash flow dynamics to insufficient planning and forecasting tools. However, the consequences are universally dire, stifling growth and curtailing the entrepreneurial spirit that fuels innovation and competition in the manufacturing sector.

This article aims to demystify the complexities of cash flow management for small manufacturing business owners, CEOs, and COOs. Through actionable strategies and insights, it endeavors to guide you on how to adeptly forecast your financial future and optimize your cash reserves. By embracing the principles and practices laid out herein, you can navigate your business away from the treacherous waters of financial instability and towards the shores of sustained growth and prosperity. In doing so, you will not only safeguard your business’s present but also secure its future, ensuring that the gears of your manufacturing enterprise continue to turn smoothly, powered by a well-managed and robust cash flow.

Let’s dive into the core of cash flow management, unveiling the strategies and insights necessary for small manufacturing business leaders to maintain financial stability and drive growth.

Part 1: Understanding Cash Flow Dynamics in Manufacturing

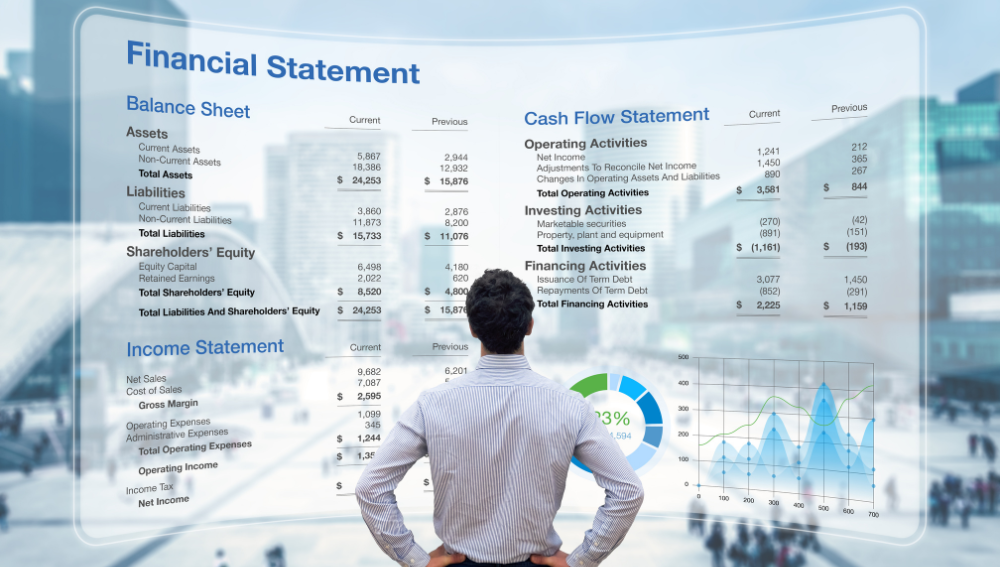

Cash flow, the net amount of cash being transferred into and out of a business, is the heartbeat of any manufacturing operation. In manufacturing, cash flows are particularly complex, shaped by the intricacies of production processes, inventory management, and customer and supplier relationships. Understanding these dynamics is the first step toward mastering cash flow management.

Key inflows primarily come from customer payments. The timing and reliability of these payments can vary significantly, influenced by market demand, the nature of contracts, and the payment terms negotiated. Outflows encompass a wide range of expenses, including raw materials, labor, machinery maintenance and upgrades, and overheads such as utilities and rent. Manufacturing businesses often face significant upfront costs before any revenue can be generated, leading to periods of cash outflow before inflow.

The cyclical nature of production and the lead times for both receiving supplies and manufacturing products mean that cash flow needs to be carefully managed to align with these cycles. Seasonal demand can exacerbate these challenges, with periods of high demand requiring additional investment in inventory and labor, followed by lulls that may see reduced cash inflow.

Part 2: Effective Cash Flow Forecasting Techniques

Forecasting is a critical tool for anticipating and managing these fluctuations in cash flow. A well-constructed cash flow forecast provides a roadmap of expected cash inflows and outflows over a given period, allowing manufacturers to plan for future financial needs.

Creating a cash flow forecast involves several key steps:

- Identify all potential sources of cash inflow and outflow, including all operational, investment, and financing activities.

- Estimate the timing and amount of each cash flow, based on historical data, contracts, and realistic assumptions about future operations.

- Consider different scenarios to understand how changes in the market, production delays, or other factors could impact cash flow.

Utilizing forecasting software can greatly enhance the accuracy and efficiency of this process, enabling more sophisticated analyses and the ability to quickly update forecasts as conditions change.

Part 3: Strategies for Optimizing Cash Flow

With a solid understanding of cash flow dynamics and a reliable forecast in hand, small manufacturers can employ several strategies to optimize cash flow:

- Inventory management: Adopting approaches such as Just-In-Time (JIT) can significantly reduce inventory costs while ensuring that production needs are met. This requires careful coordination with suppliers and a clear understanding of production schedules.

- Negotiating favorable payment terms: Working with suppliers to extend payment terms and with customers to shorten them can improve cash flow. Offering discounts for early payment from customers can also accelerate cash inflows.

- Cost control: Regularly reviewing and adjusting production processes and overheads can identify savings that improve cash flow. Lean manufacturing principles can be particularly effective in reducing waste and improving efficiency.

- Accessing finance: For periods of significant cash outflow, external financing options such as lines of credit, invoice financing, or asset-based lending can provide necessary liquidity.

Implementing These Strategies

Implementing these strategies requires a proactive approach to financial management. Regularly reviewing financial reports, staying close to the details of production processes, and maintaining strong relationships with suppliers and customers are all essential practices. As market conditions and business needs evolve, so too should your approach to cash flow management, ensuring that your business remains on solid financial footing regardless of the challenges it faces.

By understanding the unique cash flow dynamics of the manufacturing sector, accurately forecasting future financial needs, and employing effective strategies to manage cash flow, small manufacturers can navigate the complexities of their industry and steer their businesses toward sustained success.

Action Plan

To transform the insights and strategies discussed into tangible outcomes, small manufacturing business leaders need a structured action plan. This plan should empower you to forecast accurately and optimize your cash flow, setting a solid foundation for growth and stability. Here’s how you can put these principles into practice:

Monthly Actions

- Review Cash Flow Statements: Begin each month by reviewing your cash flow statement from the previous month. This helps you understand actual inflows and outflows compared to forecasts, highlighting variances that need addressing.

- Update Cash Flow Forecasts: Based on your review, update your cash flow forecasts. Incorporate any new information about market conditions, production changes, or financial commitments that could affect future cash flows.

- Monitor Inventory Levels: Assess inventory levels in line with your production schedule and demand forecasts. Adjust orders to suppliers to maintain optimal inventory levels, avoiding both excess stock and stockouts.

- Invoice Promptly and Follow Up on Receivables: Ensure invoices are sent as soon as goods are delivered or services are rendered. Implement a systematic approach for following up on outstanding invoices to improve cash inflow timing.

Quarterly Actions

- Evaluate Supplier and Customer Terms: Revisit the terms negotiated with suppliers and customers. If cash flow pressures persist, negotiate more favorable terms, such as extended payment periods with suppliers or shorter payment terms with customers.

- Review Financing Needs and Options: Assess whether there’s a need for external financing to cover cash flow gaps. If so, explore options like lines of credit, invoice financing, or other suitable financial products.

- Analyze Cost Efficiency: Conduct a thorough review of production processes and overheads. Identify areas for cost reduction without compromising on quality or output. Implement lean manufacturing techniques to enhance efficiency.

- Adjust Forecasts for Seasonal Variations: Update your cash flow forecasts to account for seasonal demand changes. Plan for inventory buildup and additional labor if needed, ensuring financing is in place to cover these periods.

Annual Actions

- Strategic Review and Planning: Conduct an annual strategic review of your business operations, market position, and financial performance. Use this review to set goals for the coming year, including specific cash flow targets.

- Invest in Forecasting and Financial Management Tools: If you haven’t already, consider investing in more sophisticated tools for financial management and forecasting. The right technology can provide deeper insights and improve decision-making.

- Develop a Contingency Plan: Create or update your contingency plan to address potential financial or operational crises. This plan should include strategies for rapid cost reduction, emergency funding sources, and operational adjustments to preserve cash flow.

- Engage with Stakeholders: Update stakeholders, including investors, lenders, and major customers, on your business’s financial health and outlook. Transparent communication can strengthen relationships and support negotiations for favorable terms.

Implementing the Action Plan

- Assign Responsibility: Designate team members to be responsible for each action area. Clear accountability ensures that tasks are completed and goals are met.

- Track Progress: Use a dashboard or tracking tool to monitor progress against each action point. Regular updates will keep your team focused and allow for adjustments as needed.

- Celebrate Success: Recognize and celebrate achievements in improving cash flow management. This reinforces the importance of these efforts and motivates your team to continue striving for financial excellence.

By following this action plan, small manufacturing business leaders can proactively manage their cash flow, ensuring their operations are resilient, responsive, and primed for growth.

Conclusion

In the complex and competitive landscape of manufacturing, mastering cash flow management is not just a financial exercise; it’s a strategic imperative. The ability to forecast and optimize cash flow separates the businesses that navigate through turbulent times from those that find themselves adrift. For small manufacturers, the stakes are even higher, as resources are limited and the margin for error is small.

The strategies and action plan outlined in this article are designed to equip small manufacturing business leaders with the tools and insights needed to ensure their operations are not just surviving but thriving. By understanding the unique cash flow dynamics of manufacturing, employing effective forecasting techniques, and implementing strategies to optimize cash flow, businesses can achieve financial stability and drive sustainable growth.

As we conclude, remember that cash flow management is an ongoing process. It demands vigilance, adaptability, and a proactive approach to financial planning. The economic landscape is ever-changing, and so are the challenges and opportunities for your business. Staying informed, prepared, and agile will enable you to steer your manufacturing enterprise toward a prosperous future.

Let this article serve as your guide and inspiration to embrace the principles of effective cash flow management. With dedication and strategic action, you can transform financial insight into operational excellence and secure the longevity and success of your business.

#ManufacturingExcellence #CashFlowManagement #SmallBusinessGrowth #FinancialForecasting #OperationalEfficiency